The Ultimate Guide to Diesel Fuel Pumps: Selecting the Right Choice for Your Business

In today’s world, businesses that rely on heavy machinery and vehicles often depend on the performance and efficiency of their diesel engines. A critical component of these engines is the fuel pumps diesel, which play a vital role in delivering fuel from the tank to the engine. In this comprehensive guide, we’ll delve into the significance of diesel fuel pumps, their types, maintenance, and how to choose the right one for your needs. This information is essential for anyone in the industry, especially those involved in the fields of diesel engine parts and spare parts suppliers.

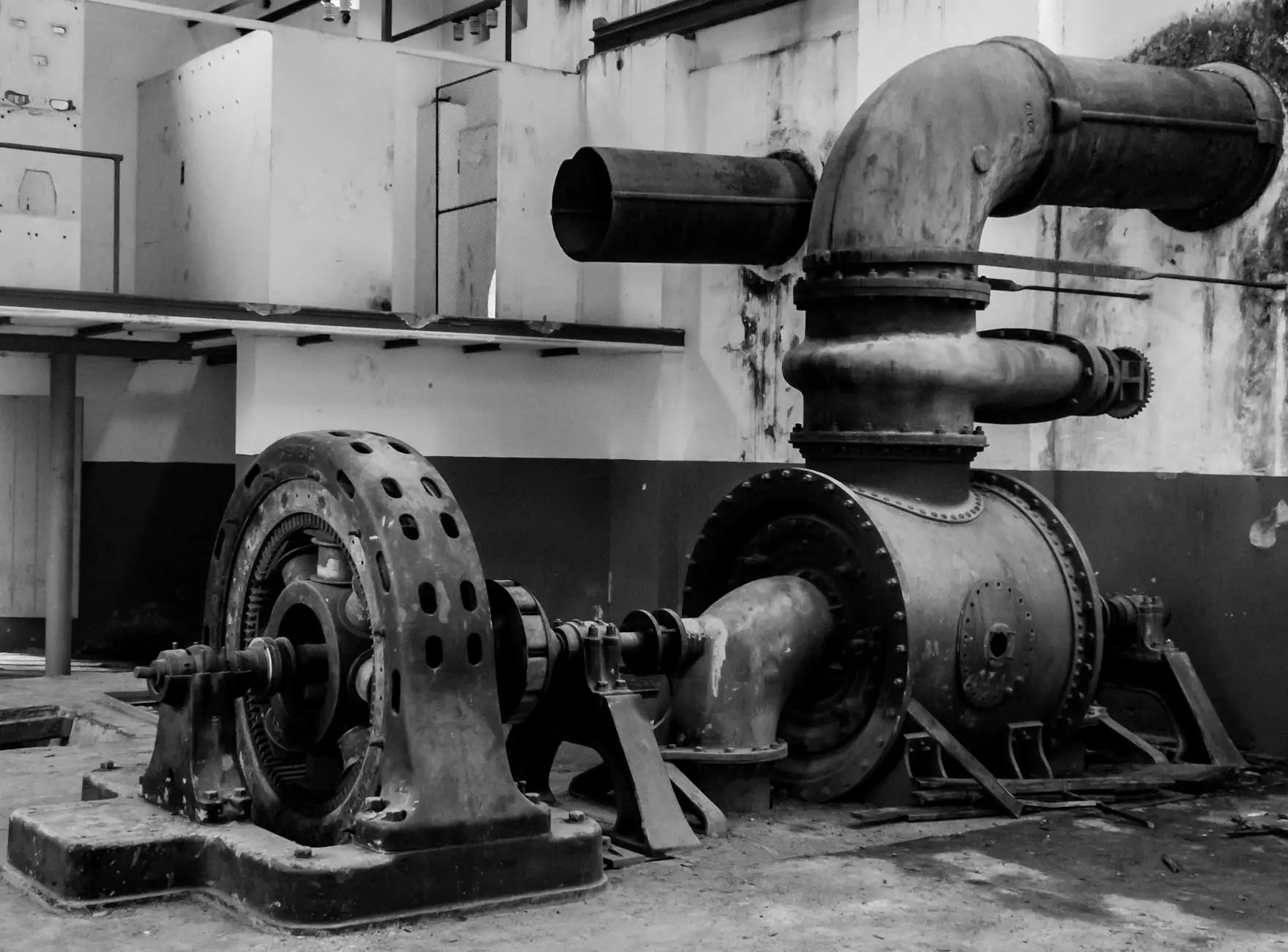

Understanding Diesel Fuel Pumps

Diesel fuel pumps are mechanical devices used to transfer diesel fuel from the fuel tank to the engine’s fuel injection system. They are engineered to create pressure in the fuel system, ensuring that the diesel reaches the combustion chamber efficiently. The performance of a diesel engine is heavily reliant on the reliability and efficiency of its fuel pump.

Types of Diesel Fuel Pumps

- Gear Pumps: These are positive displacement pumps that rely on rotating gears to propel the fuel. They are known for their robust construction and capability to handle thicker fluids.

- Rotary Pumps: Similar to gear pumps, rotary pumps use a rotating mechanism to create suction and push fuel. They are compact and commonly used in modern diesel engines.

- Diaphragm Pumps: This type of pump uses a diaphragm to dispense fuel. They are often used in low-pressure systems and are excellent for fuel transfer.

- Electric Fuel Pumps: These pumps use electricity to operate and provide reliable pressure without the need for manual intervention. They are widely used in automotive applications.

Why Fuel Pumps Are Crucial for Diesel Engines

The efficiency of fuel pumps diesel directly affects the performance of diesel engines. Here’s why they are crucial:

- Fuel Delivery: A diesel engine requires a consistent supply of fuel to operate efficiently. Without a reliable fuel pump, engine performance can degrade, leading to reduced power and increased emissions.

- Fuel Pressure Maintenance: Maintaining the correct fuel pressure is essential for optimal combustion. Fuel pumps ensure that the necessary pressure is maintained throughout the engine's operation.

- Engine Longevity: By ensuring the appropriate fuel flow and preventing issues like cavitation, a high-quality fuel pump can dramatically extend the life of a diesel engine.

How to Choose the Right Diesel Fuel Pump

When selecting a diesel fuel pump, there are several factors to consider. Here’s a detailed look at the key considerations:

1. Application Requirements

Evaluate the specific needs of your application. Are you using the pump for a light-duty vehicle, or is it for heavy machinery? Understanding the demands of your system will guide you toward the appropriate pump type.

2. Pump Performance Specifications

Consider the flow rate and pressure specifications required for your diesel engine. Ensure that the pump you choose meets or exceeds these specifications.

3. Compatibility with Diesel Fuel

Diesel fuels can vary in viscosity and chemical composition. Ensure that your selected fuel pump is compatible with the type of diesel you will be using, especially if you are considering biodiesel blends.

4. Quality and Reliability

Invest in high-quality pumps from reputable manufacturers. Research brands that are known for their reliability and durability. Look for customer reviews and ratings, and consider suppliers like client-diesel.com that provide verified products.

5. Maintenance and Support

Choose a fuel pump that is easy to maintain and for which replacement parts are readily available. Consider suppliers that offer excellent customer support and guidance on maintenance practices.

Maintenance of Diesel Fuel Pumps

Proper maintenance of diesel fuel pumps is pivotal to their longevity and performance. Below are best practices:

Regular Inspections

Conduct regular inspections to identify any signs of wear, leaks, or damage. Early detection of issues can prevent costly breakdowns.

Fuel Quality Control

Use clean, high-quality diesel fuel to minimize sediment buildup and prevent clogging in the fuel pump. Regularly check the fuel for contaminants.

Scheduled Replacements

Be aware of your fuel pump’s lifespan and adhere to manufacturer guidelines for replacement intervals. Waiting too long can lead to engine performance issues.

Professional Servicing

Consider professional servicing for your fuel pump during major maintenance checks. Timing can be crucial, especially in commercial applications where downtime can be costly.

Common Issues with Diesel Fuel Pumps

Understanding the common issues that can arise with diesel fuel pumps can help you mitigate risks effectively:

- Cavitation: Caused by inadequate fuel supply or excessive pressure drops, leading to damage within the pump.

- Contamination: Dirt or debris in the fuel system can block fuel filters and strain the pump.

- Wear and Tear: Over time, regular use can lead to wear, resulting in diminished performance and efficiency.

- Electrical Failures: For electric fuel pumps, electrical faults can cause complete pump failure.

Conclusion

In conclusion, fuel pumps diesel are an integral part of the operation of diesel engines in various sectors. Understanding their function, types, selection criteria, and maintenance practices is essential for anyone involved in diesel engine management or in the supply of diesel engine parts. By leveraging high-quality components from reliable suppliers like client-diesel.com, businesses can ensure optimal performance and longevity of their diesel engines, ultimately leading to improved operational efficiency and reduced costs.

Investing time in the right fuel pump will pay dividends—we encourage you to prioritize your needs carefully, do your research, and leverage expert advice to make informed decisions. Your diesel engine deserves the best, so don’t compromise on quality.